System Modifications & Upgrades

Pick a Service

Honeyman Water Site Services

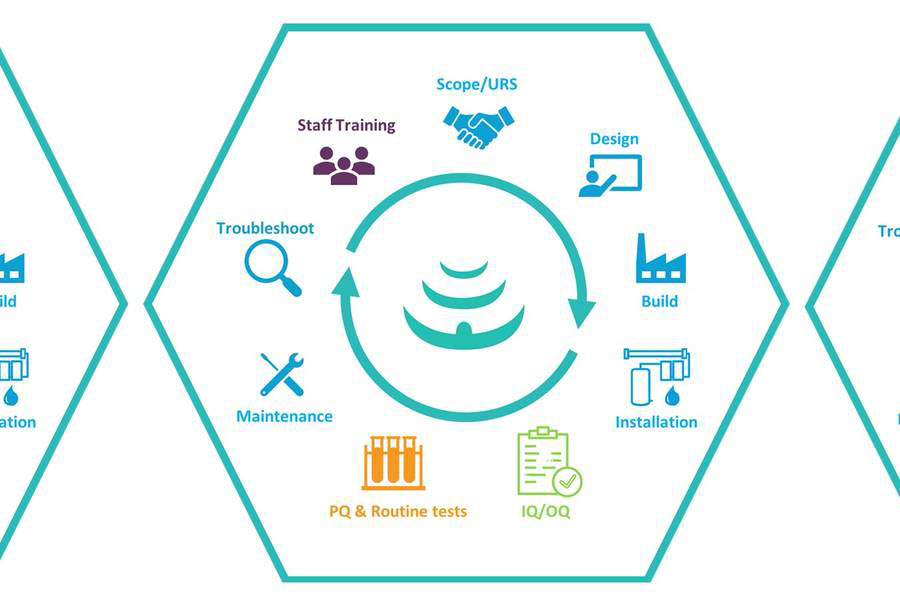

Focussing on the pharmaceutical, health and beauty sectors, our experienced site services engineers offer a range of services, aimed at increasing your output, help you meet regulatory requirements and improve reliability of your current purified water, WFI or pure steam systems.

Utilising state of the art equipment which includes Orbitalum orbital TIG welding sets, GF cutters and fully coded welders, Honeyman Water can offer the following upgrade and pipework modification services:

- Heat exchanger replacement or upgrade

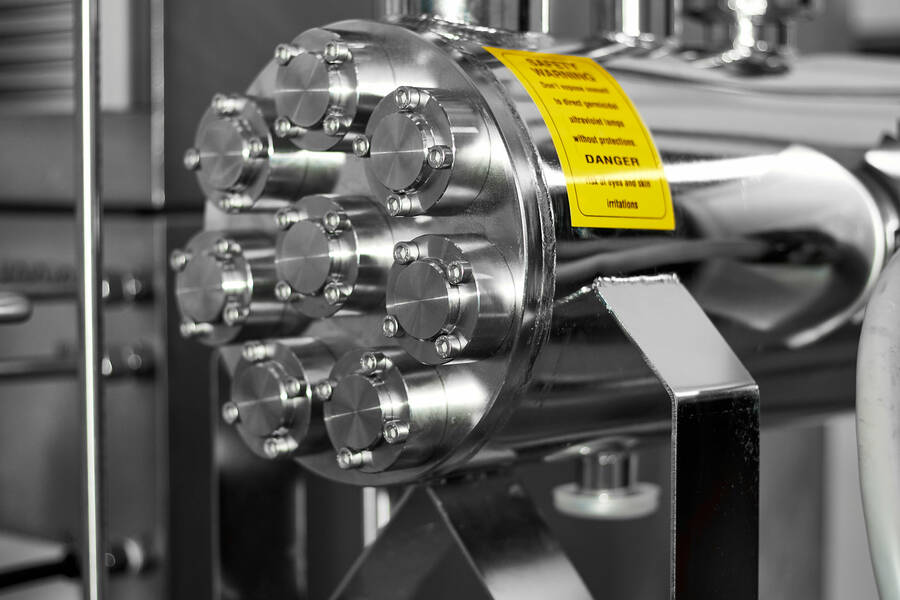

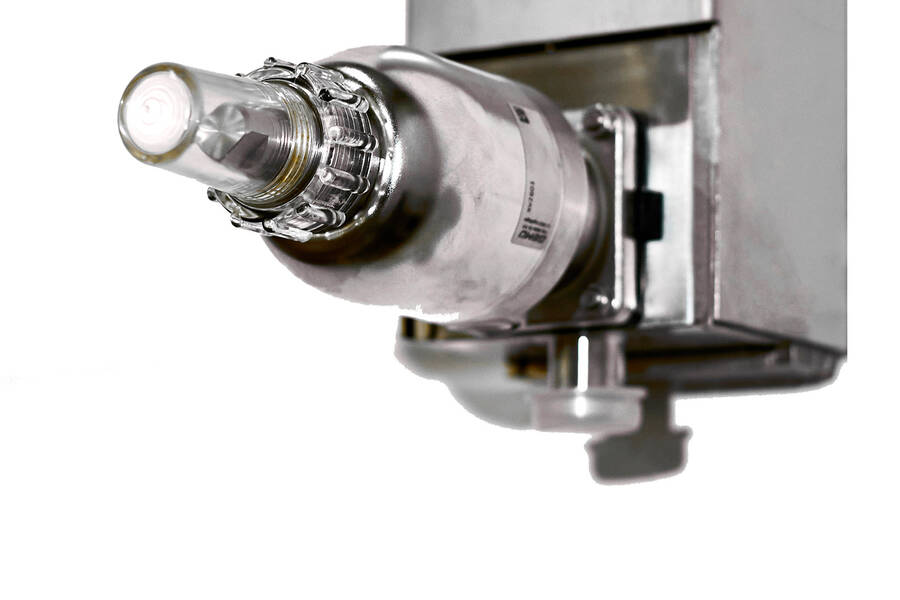

- Upgrade of UV reactors

- Installation and or upgrade of Ozone generators and instrumentation

- Upgrades from manual to actuated point of use valves

- Modifications to fit or replace TOC analyser instrumentation

- HMI – Control system upgrades,

- Pipework modifications and loop extensions

- Installation of new centrifugal pumps – including pipework modifications

- Skid manufacture including pump, dosing, distribution and CIP skids etc.

All pipe work (modifications) are orbitally welded, fully passivated, all parts are made from SS316L SF1 as standard. Our documentation pack includes; weld maps, welding qualifications, 3.1b material certification for all wetted parts. Where needed fully schedules are submitted for additional equipment, instrumentation and valves.

To discuss your water or steam requirements, please contact us with your details and a brief introduction, so we can arrange a call back at a time convenient to you.

Our Customers: